We use cookies to make your experience better. To comply with the new e-Privacy directive, we need to ask for your consent to set the cookies. Learn more.

The Kerakoll H40 Range is a collective a Gel-Adhesives for ceramic, porcelain tiles and natural stone.

The new Kerakoll H40 Range is a tile adhesive that has been designed to be better than ever before. Thanks to its innovative formulation and Kerakoll's persistent drive to produce the best products on the market. The H40 Range is perfect for use in a wide range of substrates with a variety of different materials. With its improved performance, the H40 Range is the ideal choice for tile installation projects that require a reliable tile adhesive.

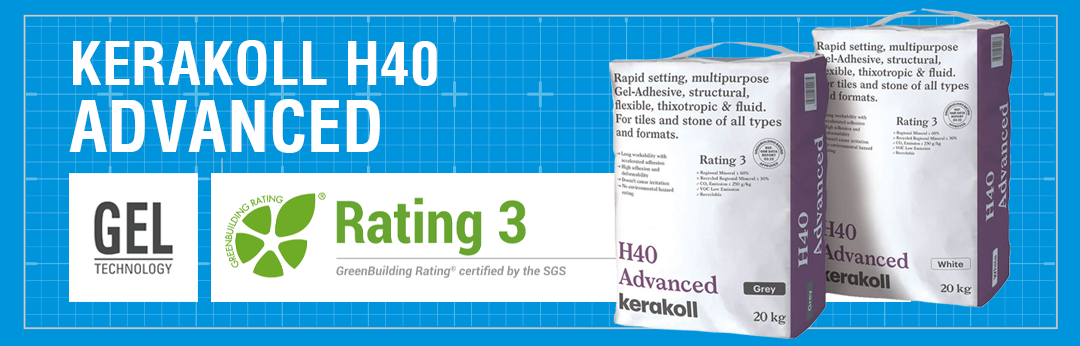

H40 Advanced

Rapid setting, multipurpose gel‑adhesive, structural, flexible, thixotropic & fluid. For tiles and stone of all types and formats.

- Long workability with accelerated adhesion

- High adhesion and deformability

- Doesn’t cause irritation

- No environmental hazard rating

The H40 Advanced is formidable in even the most extreme on-site conditions.

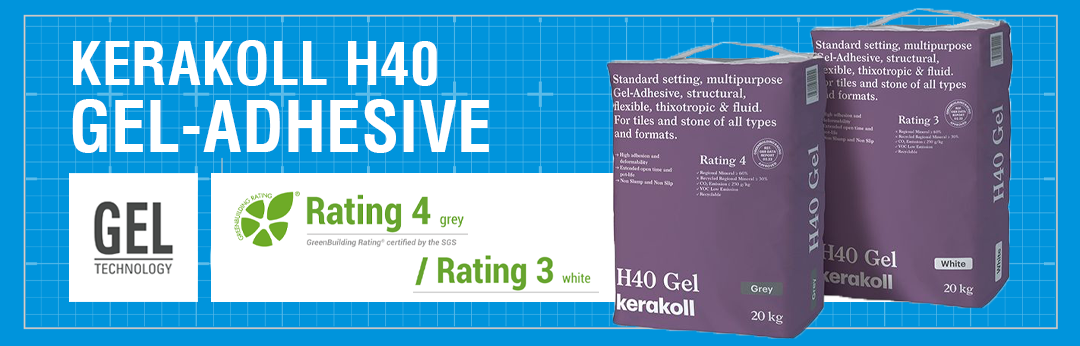

H40 Gel

Standard setting, multipurpose gel‑adhesive, structural, flexible, thixo & fluid. For tiles and stone of all types and formats.

- High adhesion and deformability

- Extended open time and pot‑life

- Non slump and non slip

Say hello to the next generation of standard-setting gel adhesive with extended workability and a solution for (almost) every situation. Find out more on our website.

H40 Extreme

Highly deformable and workable hybrid gel‑adhesive, tested for extreme conditions and uses.

- Very fast bonding

- Stress resistant

- Easy to spread

Get extreme performance with the H40 Extreme Hybrid Gel Adhesive. Five times less viscous than a traditional polyurethane adhesive and ten times more deformable than generic S2 adhesives.

Kerakoll H40 Advanced - Suitable Substrates

- Existing tiles

- Waterproofing products

- Heating systems

- Cement-based screeds

- Concrete substrates

- Plasterboard

- Fibro-cement slabs

- Gypsum and anhydrite

- Asphalt screeds

- Brick/blockwork

- Lime and cement-based plasters/renders

- Thermal insulation panelling systems

- Insulating panels

- Impact noise insulation sheets

- Timber - metal - PVC

Kerakoll H40 Advanced - Suitable Materials

- Porcelain tiles

- Laminated stoneware

- Low thickness slabs

- Ceramic tiles

- Large size 300x150 cm slabs

- Marble - natural stone

- Recomposed materials

- Glass mosaics

- Glass tiles

- Thermal and acoustic insulation

- Terracotta - klinker

KerakollH40 Gel-Adhesive - Suitable Substrates

- Existing tiles

- Waterproofing products

- Heating systems

- Cement-based screeds

- Concrete substrates

- Plasterboard

- Fibro-cement slabs

- Gypsum and anhydrite

- Asphalt screeds

- Brick/blockwork

- Lime and cement-based plasters/renders

- Thermal insulation panelling systems

- Insulating panels

- Impact noise insulation sheets

- Timber - metal - PVC

Kerakoll H40 Gel-Adhesive - Suitable Materials

- Porcelain tiles

- Laminated stoneware

- Low thickness slabs

- Ceramic tiles

- Large size 300x150 cm slabs

- Marble - natural stone

- Recomposed materials

- Glass mosaics

- Glass tiles

- Thermal and acoustic insulation

- Terracotta - klinker

Kerakoll H40 Extreme - Suitable Substrates

- Existing tiles

- Heating systems

- Cement-based screeds

- Asphalt screeds

- Concrete

- PlasterboardFibro-cement slabs

- Gypsum and anhydrite

- Cellular concrete

- Brick

- Lime and cement-based plasters/renders

- Finished and subsequently plastered thermal

- Insulation panelling systems

- Impact noise insulation sheets

- Cracked screeds

- Uncured damp screeds

Kerakoll H40 Extreme - Suitable Materials

- Porcelain tiles

- Laminated stoneware

- Porcelain tile with resin back

- Very large formats

- Low thickness slabs

- Ceramic tiles

- Marble - natural stone

- Marble with resin back

- Recomposed materials

- Cement-based recomposed materials

- Glass mosaics

- Glass tiles

- Thermal and acoustic insulation

- Terracotta - klinker

- Metal tiles

Instructions Of Use For Kerakoll H40 Range

Kerakoll H40 Gel Tile Adhesive – Instructions for use:

Preparation of the substrate:

Substrates must comply with BS 5385, parts 1-5, be level, cured, undamaged, compact, rigid, dry and free from any debonding agents. It is good practice to dampen highly absorbent concrete substrates or apply a coat of Kerakoll Primer A Eco. Anhydrite substrates must have a residual humidity ≤ 0,5 CM-%. Cement-based screeds must have a residual humidity ≤ 2 CM-%. Anchored substrates must comply with BS 8204 and anhydrite with underfloor heating must have a residual humidity ≤ 0,3 CM-%.

Please note: For pre-treatment of internal special substrates such as metal, timber, PVC, asphalt/bitumen, gypsum and anhydrite, prime with Kerakoll Keragrip Eco Primer.

Mixing:

Mixing water (EN 12004-26): Grey ≈ 23% – 29% by weight, White ≈ 26% – 33% by weight.

Mixing water on-site: For low thickness laying and full wettability: Grey ≈ 5.7 l/1 bag, White ≈ 6.6 l / 1 bag

On walls, for high and low thickness laying: Grey ≈ 4.5 l/1 bag, White ≈ 5.1 l / 1 bag

The amount of water to be added to Kerakoll H40 Gel Tile Adhesive, indicated on the packaging, is an approximate guide. It is possible to obtain mixtures with the consistency of variable thixotropy according to the application to be made.

Application:

To guarantee structural adhesion it is necessary to apply a layer of Kerakoll H40 Gel Tile Adhesive sufficient to cover the entire back of the coating material.

Large, rectangular sizes with sides > 60 cm and low thickness sheets may require adhesive to be applied directly to the back of the material.

Check samples to make sure the adhesive has been transferred to the back of the material.

Create elastic expansion joints:- ≈ 10 m2 in external applications (approx. 3×3 m), – ≈ 40 m² in internal applications (8×5 m) with underfloor heating, – ≈ 100 m² in internal applications (10×10 m) without underfloor heating.

– every 8 metres in length, narrow applications. Respect all structural, fractionizing and perimeter joints present in the substrates.

Technical Data:

Adhesive thickness: from 2 to 15mm

The temperature of the air, substrates and materials: from +5°C to +35°C

Pot life at +23°C: – grey ≈ 4 hrs,- white ≈ 4 hrs

Open time at +23°C: (BIII tile):- grey ≥ 60 minutes, -2- white ≥ 60 minutes

Foot traffic/grouting of joints at +23°C (BIa tile):- grey ≈ 16 hrs, – white ≈ 16 hrs

Foot traffic/grouting of joints at +5°C(BIa tile): – grey ≈ 42 hrs, – white ≈ 24 hrs

Grouting in walls at +23°C (BIa tile)- grey ≈ 12 hrs, – white ≈ 12 hrs

Ready for use at +23°C / +5 °C (BIa tile): – light foot traffic ≈ 1/2 days, – heavy traffic ≈ 3/5 days, – swimming pools (+23°C) ≈ 14 days

Coverage per mm thickness: – grey (mixing ratio 26%) ≈ 1.3 kg/m2, – white (mixing ratio 30%) ≈ 1.2 kg/m2

Kerakoll H40 Advanced Gel Tile Adhesive – Instructions for use:

Preparation of the substrate:

Substrates must comply with BS 5385, parts 1-5, be level, cured, undamaged, compact, rigid, dry and free from any debonding agents. It is good practice to dampen highly absorbent concrete substrates or apply a coat of Kerakoll Primer A Eco. Anhydrite substrates must have a damp content of ≤ 0.5 % CM and be adequately sanded, cleaned using a suitable vacuum cleaner and primed.Please note:

For pre-treatment of internal special substrates such as metal, timber, PVC, asphalt/bitumen, gypsum and anhydrite, prime with Kerakoll Keragrip Eco Primer.

Mixing:

Mixing water (EN 12004-26): Grey ≈ 20% – 23% by weight, White ≈ 28% – 30% by weight.

Mixing water on-site: For low thickness laying and full wettability: Grey ≈ 4.6 l/1 bag, White ≈ 6 l / 1 bag

On walls, for high and low thickness laying: Grey ≈ 4.1 l/1 bag, White ≈ 5.5 l / 1 bag

The amount of water to be added to Kerakoll H40 Advanced Gel Tile Adhesive, indicated on the packaging, is an approximate guide. It is possible to obtain mixtures with consistency of variable thixotropy according to the application to be made.

Application:

To guarantee structural adhesion it is necessary to apply a layer of Kerakoll H40 Advanced Gel Tile Adhesive sufficient to cover the entire back of the coating material.

Large, rectangular sizes with sides > 60 cm and low thickness sheets may require adhesive to be applied directly to the back of the material.

Check samples to make sure the adhesive has been transferred to the back of the material.

Create elastic expansion joints:- ≈ 10 m2 in external applications (approx. 3×3 m), – ≈ 40 m² in internal applications (8×5 m) with underfloor heating, – ≈ 100 m² in internal applications (10×10 m) without underfloor heating.

– every 8 metres in long, narrow applications. Respect all structural, fractionizing and perimeter joints present in the substrates.

Technical Data:

Adhesive thickness: from 2 to 15mm

Temperature of the air, substrates and materials: from +5°C to +35°C

Pot life at +23°C: – grey ≈ 1 hr,- white ≈ 1 hr

Open time at +23°C: (BIII tile):- grey ≥ 45 minutes, -2- white ≥ 45 minutes

Correction Time – White and Grey: 6 minutes

Foot traffic/grouting of joints at +23°C (BIa tile):- grey ≈ 3 hrs, – white ≈ 3 hrs

Foot traffic/grouting of joints at +5°C(BIa tile): – grey ≈ 7 hrs, – white ≈ 7 hrs

Grouting in walls at +23°C (BIa tile)- grey ≈ 2 hrs, – white ≈ 2 hrs

Ready for use at +23°C / +5 °C (BIa tile): – light foot traffic ≈ 6 – 16 hrs, – heavy traffic ≈ 24 – 28 hrs, – swimming pools (+23°C) ≈ 7 days

Coverage per mm thickness: – grey (mixing ratio 23%) ≈ 1.3 kg/m2, – white (mixing ratio 28.5%) ≈ 1.2 kg/m2

Kerakoll H40 Extreme Gel Tile Adhesive – Instructions for use:

Preparation of the substrate:

All the substrates must be flat, compact, free from dust, loose particles and debonding agents and not be subject to moisture rising. Applying a coat of diluted Kerakoll Primer A Eco on very absorbent cement-based substrates is best.

Please note: For pre-treatment of internal special substrates such as sheet metal, metal, timber, rubber floors and PVC, clean with Kerakoll Keragrip Eco Pulep.

Mixing:

Single Pack: Part B is found inside the pack. Respect the preset ratio of 8.6 : 1.4.

Remix part B into the bucket containing part A, carefully mixing the two parts uniformly until a smooth, even coloured mixture is obtained.

For ease of mixing and application, it is recommended to store packs of Kerakoll H40 Extreme Gel Tile Adhesive at a temperature of ≈ +20 °C for at least 2/3 days prior to use.

Application:

Kerakoll H40 Extreme can be applied with a suitable notched trowel, to be chosen according to the size and type of the tile. Using the smooth part of the trowel, apply a fine layer of product, pressing down onto the substrate in order to ensure maximum adhesion. Press down each tile into the ribbed adhesive to allow for maximum coverage of the surface.

To guarantee structural adhesion it is necessary to apply a layer of Kerakoll H40 Extreme Gel Tile Adhesive sufficient to cover the entire back of the coating material.

Large, rectangular sizes with sides > 60 cm and low thickness sheets may require adhesive to be applied directly to the back of the material.

Check samples to make sure the adhesive has been transferred to the back of the material.

Create elastic expansion joints:- ≈ 10 m2 in external applications (approx. 3×3 m), – ≈ 25 m² in internal applications (8×5 m), and – every 8 metres in long, narrow applications. Respect all structural, fractionizing and perimeter joints present in the substrates.

Cleaning:

Clean the tools and any residues of Kerakoll H40 Extreme from the coated surfaces with water while the adhesive is still fresh. Once hardened, the adhesive can only be removed mechanically or using Kerakoll Fuga Shock Eco cleaner.

Technical Data:

Mixing Ratio: part A : part B = 8.6 : 1.4

Adhesive thickness: from 2 to 15mm

The temperature of the air, substrates and materials: from +5°C to +35°C

Pot life at +23°C: 110 minutes

Pot life at +35°C: 80 minutes

Open time at +23°C (BIII tile): 23°C = 180 minutes, +35°C = 90 minutes

Correction time (BIII tile): 23°C = 120 minutes, +35°C = 60 minutes

Foot traffic/grouting of joints at +23°C (BIa tile): 4 hrs

Foot traffic/grouting of joints at +5°C(BIa tile): 15 hrs

Ready for use at +23°C / +5 °C (BIa tile): – light foot traffic ≈ 6 – 20 hours, – heavy traffic ≈ 12-24 hours, – swimming pools (+23°C) ≈ 3 days

Coverage per mm thickness: 1.45 kg/m2